|

Thermal treatment

What about the process ?

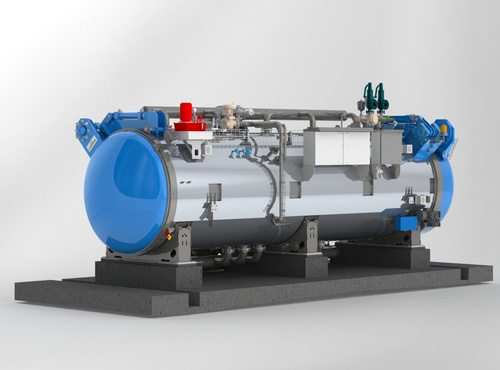

Sterilization by Water Spraying (directly heated by Steam injection):

Water is injected at the bottom of the retort until it reaches a certain level to allow the pump to correctly function (or the water is keep from the previous cycle) using an LAGARDE AUTOCLAVES exclusivity.

With this special device, spray nozzles, this water is in turn heated by injecting steam directly in the retort (no external heat exchanger requested) and between each stack.

For the cooling, the water is sucked in by the pump and circulates on treated products. These same spray nozzles designed and patented by LAGARDE AUTOCLAVES which are located on the side of each baskets ensure the performance cooling also.

Sterilization by Steam/Air (Heating and sterilisation phase: )

The steam, which has no physical barrier, is introduced directly and automatically into the autoclave and is distributed geometrically by distributors. A ventilation system, permanently controlled by the regulation system, and especially designed to have an optimized performance, facilitates the circulation of steam in any part of the equipment in order to guarantee a perfect temperature homogeneity.

It is not necessary to preheat water neither in the bottom of the autoclave, nor in the pipe, nor added water, since steam is injected directly between the baskets.

When the sterilization temperature is reached, the fan remains in operation and thus participates in an even more effective heat penetration at the heart of the product. Steam has the best calorific value of all services (3 to 100 times better than water for example). The high precision measuring system coupled with the SAMANTHA © regulation system allows to have a pressure and backpressure treatment without inertia, in real time, before, during and after the entire sterilization phase.

|

.jpg?1544394815030)